What is Stainless Steel Water Tank (Bolted-Connection) ?

The bolted-connection stainless steel water tank is a modular square or rectangular water storage tank composed of 1×1 meter stainless steel panels. The panels are connected by bolts and sealed with food-grade EPDM gaskets, allowing on-site assembly without welding.

The tank structure is flexible in size and height, as the overall capacity is determined by the number of panels assembled. Made from stainless steel 304/2B (SUS 304) or stainless steel 316 (SUS 316) stainless steel, it offers excellent corrosion resistance, high hygiene standards, and a long service life, making it suitable for potable water and industrial applications.

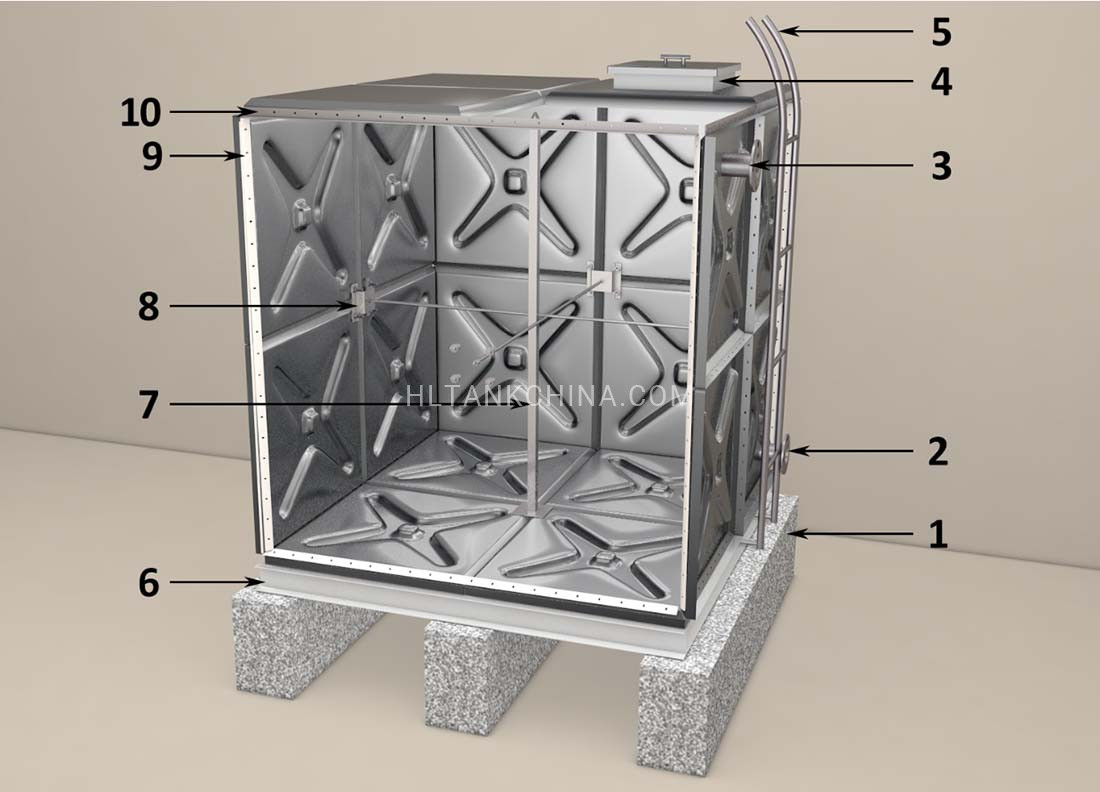

(Stainless steel water tank inside view)

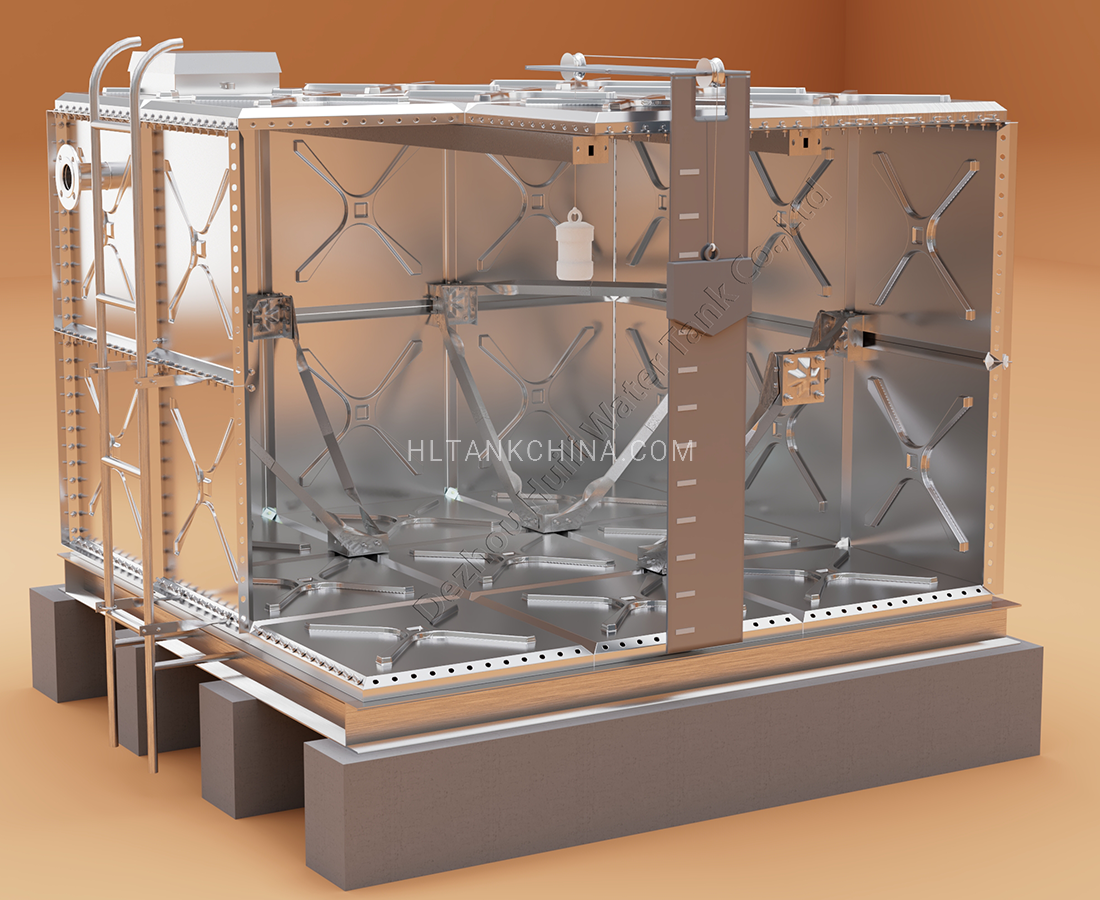

(Stainless steel water tank outside view)

(Stainless steel water tank roof view)

(Stainless steel water tank overview)

TECHNICAL DATA (BOLTED TYPE)

PANELS

●SURFACE DESIGN

“X” shape

●MATERIAL

1.Food grade SS 304/2B

2.Food grade SS 316L

●SIZE & WEIGHT

1.The size of stainless steel panels are produced by standard with 1.22*1.22m,1*1 m, 1*0.5 m and 0.5*0.5 m.

2. The panel thickness is depends on tank height.

3.The maximum height available is 5 meters (Need to add C-channel external reinforcement if over 5 m height).

●WATER TANK HEIGHT MATCHES PANEL THICKNESS.

| Height(mm) | Bottom | Side one | Side two | Side three | Side four | Side five | Roof |

|---|---|---|---|---|---|---|---|

| 1000 | 3mm | 2.5mm | / | / | / | / | 2mm |

| 1500 | 3mm | 2.5mm | 2.5mm | / | / | / | 2mm |

| 2000 | 3mm | 3mm | 2.5mm | / | / | / | 2mm |

| 2500 | 3mm | 3mm | 3mm | 2.5mm | / | / | 2mm |

| 3000 | 3mm | 3mm | 3mm | 2.5mm | / | / | 2mm |

| 3500 | 4mm | 4mm | 3mm | 2.5mm | 2.5mm | / | 2mm |

| 4000 | 4mm | 4mm | 3mm | 3mm | 2.5mm | / | 2mm |

| 4500 | 5mm | 4mm | 3mm | 3mm | 2.5mm | 2.5mm | 2mm |

| 5000 | 5mm | 4mm | 3mm | 3mm | 2.5mm | 2.5mm | 2mm |

(The standard tolerance of thickness is 0.25 mm.For example,the actual thicknesss of 3mm is 2.75mm)

●PHYSICAL PROPERTIES

| Physical Properties | Standard requirement | Result |

|---|---|---|

| Tensile strength | ≥515 Mpa | 695 Mpa |

| Yield Strength | ≥205 Mpa | 309 Mpa |

| Elongation | ≥40% | 54% |

| Hardness | ≤92 HRBS | 85 HRBS |

STAINLESS STEEL WATER TANK ACCESSORIES

The square bolted stainless steel water tank is assembled from 1×1 m panels with bolts and sealed by food-grade gaskets. It includes a manhole, vent pipe, inlet and outlet connections, internal tie rods, support, ladder, skid base and water stoppage etc.

1. Concrete beam 2. Outlet flange 3. Inlet flange 4. Manhole 5. External ladder 6. C-channel 7. Vertical support

8. Tie rod plate 9. Sealing rubber 10. Top angle bar

●BOLTS & NUTS—— 1. SS 304/2B 2. SS 316

●SKID BASE —— 1.Hot dipped galvanized 2. Painting

●INTERNAL STRUCTURE—— 1. SS 304/2B 2. SS 316

●FLANGES—— 1. SS 304/2B 2. SS 316

●SEALING RUBBER—— 1. Food grade white color EPDM 2. PVC foam

●WATER INDICATOR—— 1. Glass with brass valve 2. Float type

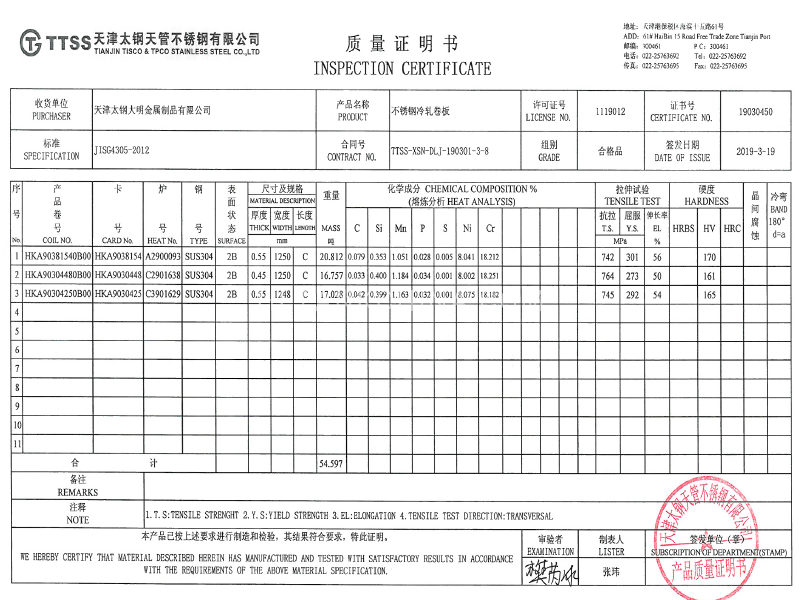

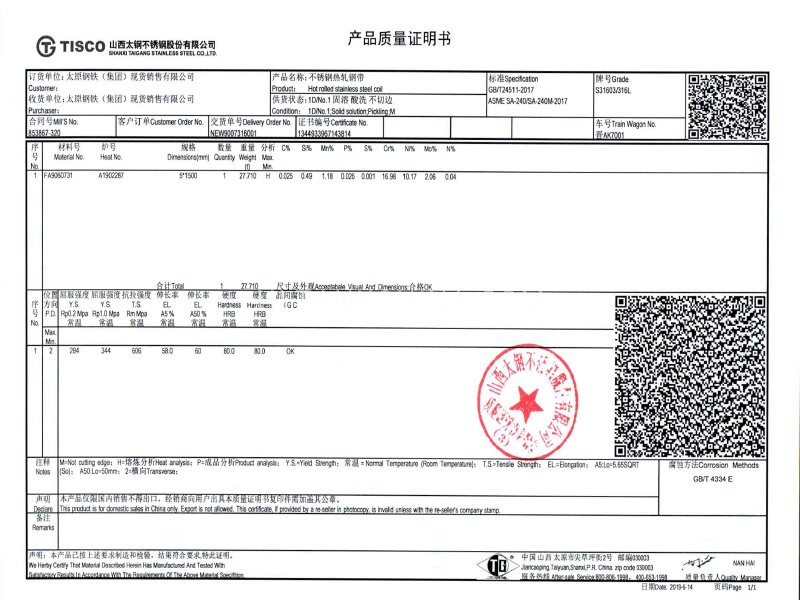

Mill Certificate for Stainless Steel Water Tank (304/2B and SS 316)

All stainless steel materials used for our water tanks are supplied with official mill certificates (MTC), confirming chemical composition and mechanical properties. Raw materials are sourced from leading stainless steel manufacturers, including large state-owned steel mills, ensuring stable quality, full traceability, and compliance with international standards. This guarantees high product reliability, durability, and safety for potable water applications.

Stainless steel 304/2B water tank advantages

Excellent corrosion resistance for most potable water applications

High hygiene level and easy to clean, suitable for drinking water storage

Good mechanical strength and structural stability

Cost-effective compared to SUS316

Widely accepted and compliant with international standards

Suitable for residential, commercial, and general industrial water storage

Stainless steel 316 water tank advantages

Superior corrosion resistance, especially against chlorides, salts, and marine environments

Excellent performance in coastal, high-humidity, and high-salinity conditions

Enhanced resistance to pitting and crevice corrosion due to molybdenum content

Suitable for aggressive industrial environments and chemical exposure

Longer service life in harsh conditions

Ideal for high-standard potable water and special industrial applications

(Stainless steel 304/2B water tank raw material mill certificate)

(Stainless steel 316 water tank raw material mill certificate)

Quality Control – Double-Sided Protective Film

As part of our strict quality control system, all stainless steel panels used for water tank production are protected with double-sided protective film throughout the forming process. This measure prevents direct contact between the stainless steel surface and forming molds, tools, and handling equipment.

By isolating the material from mechanical contact, the risk of surface damage, iron contamination, and rust spots caused by mold contact is effectively minimized. This control ensures that the original corrosion resistance and surface integrity of the stainless steel are maintained.

The protective film is removed only after panel forming and before final installation, guaranteeing clean, smooth, and defect-free stainless steel surfaces. This QC procedure ensures consistent product quality, improved durability, and compliance with potable water hygiene requirements.

Pressed Stainless Steel Water Tank Panel Fabrication Capability

We offer full in-house fabrication for stainless steel water tank panels, covering standard and customized sizes. Our production lines support panel thicknesses ranging from 2.0 mm to 6.0 mm, meeting various structural and capacity requirements.

Notably, we have the capability to manufacture heavy-duty panels up to 6 mm thick, ideal for large-capacity tanks, high water pressure applications, or demanding environments. This makes us a reliable supplier for both standard and reinforced tank designs.

Complete Engineering & Installation Support

We provide complete engineering and installation support for our water tank projects. Our services include professional shop drawings, structural design, installation manuals, and step-by-step installation videos. All drawings are prepared by experienced engineers and tailored to project requirements, applicable standards, and site conditions. During installation, we offer remote technical guidance to ensure correct assembly and safe operation. From design to final installation, we support our clients at every stage to ensure project success.

Project Case Showing

We make two types of stainless steel rectangular water tanks, one is an above SS bolted-connection rectangular water tank, One is stainless steel welding-connection rectangular water tank.

We are honored to have been selected as the trusted supplier for stainless steel water tank solutions by leading global corporations. Below projects for your reference:

-

Singapore Industrial Facility: Engineering and delivery of a 9x6x3m stainless steel bolted-connection rectangular water tank.

-

Hyundai Motor, Indonesia: Provision of a 10x6x5m stainless steel bolted-connection rectangular water tank for their manufacturing facility.

Each project reflects our strong capability in delivering customized, high-quality water storage solutions that meet the strict standards of international clients.If you have any water tank inquiries, just drop me email [email protected] or text Whatsapp:+8618505343912

Singapore: SS bolted-connection 9x6x3m (H)

Indonesia project: Hyundai Motor SS bolted-connection water tank 10x6x5m (H)

Multiple Panel Size Options – Metric & British Standard Design (Panel Pattern Optional Also)

In addition to the standard 1000 × 1000 mm modular panel design, our stainless steel water tanks are also available with 1220 × 1220 mm panels, designed in accordance with British Standard (BS) practices. This dual panel-size capability allows us to meet different regional preferences, engineering requirements, and project specifications.

The 1000 × 1000 mm panel system offers high flexibility and is widely used for international projects, while the 1220 × 1220 mm British Standard panel design reduces the total number of panels and bolted joints, improving installation efficiency for larger-capacity tanks.

Both panel systems are manufactured using certified stainless steel materials and follow the same strict quality control procedures, ensuring reliable structural performance, excellent sealing, and long-term durability for potable and industrial water storage applications.

(The 1220 × 1220 mm British Standard panel design adopts a different internal bracing layout compared with standard metric systems)

British Standard Stainless Steel Water Tank Installation Video

The British Standard stainless steel water tank installation video helps you better understand the installation process of British Standard tank systems, including panel assembly, internal support structure, and bolted connections, ensuring clear guidance and correct installation.

Related Water Tank Products

Stay In Touch With Us